Refrigerator History and Business Guide

From Ice Pits to Eco-Friendly Cooling

This refrigerator history and business guide explains how this essential machine evolved from ancient ice storage to today’s smart cooling systems. From ancient ice pits to today’s smart inverter refrigerators, this invention has reshaped food preservation, global trade, and modern living. In this refrigerator history and business guide, you’ll learn both science and strategy behind refrigeration.

“Refrigeration didn’t just cool kitchens — it unlocked food safety, logistics, and global commerce.”

1. Before Machines: Natural Cooling Methods

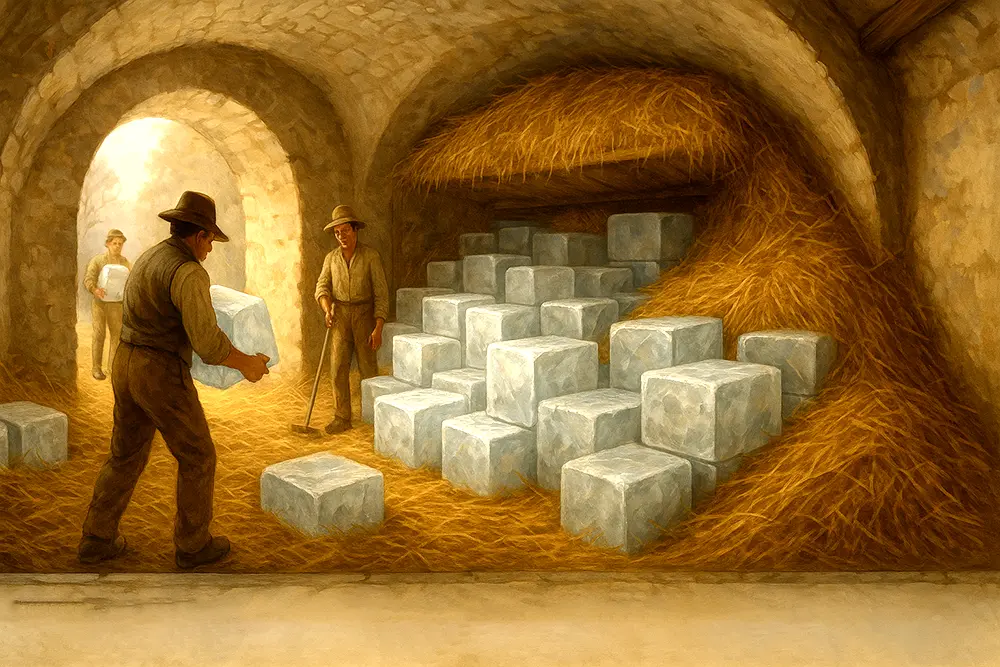

Icehouses and snow pits: Ancient civilizations stored winter ice underground with layers of straw and sawdust for insulation.

Evaporative cooling: Clay and earthen pots allowed water to evaporate, cooling the surface naturally — an early, no-electric cooling technique still used in many villages.

2. The Science Behind Refrigeration: A Key Part of Refrigerator History

Scientists discovered that evaporating a liquid under low pressure absorbs heat, setting the foundation for modern refrigeration.

-

1834–35: Jacob Perkins patented the vapor-compression refrigeration system, the same basic cycle used today — compress, condense, expand, and evaporate.

-

1851: John Gorrie built a mechanical ice maker to cool hospital rooms in tropical climates.

3. Industrial Expansion (1870s–1900s)

-

1876: Carl von Linde introduced reliable ammonia-based systems for breweries and meatpacking industries.

-

Cold storage spread to ships and railways, creating the modern cold chain that enabled global food distribution.

4. The Home Refrigerator Revolution (1900s–1930s)

Early refrigerators were expensive and often dangerous due to toxic gases like ammonia, sulfur dioxide, and methyl chloride.

-

1927: General Electric launched the Monitor-Top Refrigerator, a sealed and safe system that made home refrigeration accessible to the middle class.

“A sealed system and safer refrigerants turned the fridge from a luxury into a must-have appliance.”

5. Safer Refrigerants and Environmental Awareness (1930s–1990s)

-

CFC Era: Non-flammable CFCs (Freon) replaced toxic gases and fueled global refrigerator adoption.

-

Ozone Shock: In the 1980s, scientists discovered CFCs damaged the ozone layer. The 1987 Montreal Protocol began phasing them out.

-

HFCs followed, safer for the ozone but still high in global-warming potential.

6. Modern Refrigeration (2000s–Today)

-

Compressors: Inverter and variable-speed motors reduce energy use and noise.

-

Refrigerants: Eco-friendly gases like R-600a (isobutane) and HFO blends lower environmental impact.

-

Design: Smarter insulation, air-flow systems, antibacterial liners, and app-based temperature control make today’s fridges more efficient and hygienic.

7. How a Refrigerator Works (Simple Explanation)

-

Compressor: Pressurizes and heats the refrigerant gas.

-

Condenser Coils: Release heat; the gas becomes liquid.

-

Expansion Device: Reduces pressure; the liquid cools.

-

Evaporator Coils: Absorb heat from inside the cabin, cooling the air.

This continuous cycle keeps your food fresh.

8. Refrigerator Evolution Chart

| Era | Common Refrigerant | Safety & Environment | Typical Use | Notes |

|---|---|---|---|---|

| 1920s–30s | Ammonia, SO₂, Methyl Chloride | Toxic/Irritant | Industrial & Early Home | Replaced due to safety risks |

| 1930s–80s | CFCs (Freon) | Ozone-Depleting | Home & Commercial | Phased out by Montreal Protocol |

| 1990s–2010s | HFCs | No Ozone Harm, High GWP | Home & Commercial | Gradual reduction worldwide |

| 2010s–Today | R-600a, HFOs, CO₂, NH₃ | Low GWP, Safe by Design | Home & Industrial | Eco-friendly and efficient |

9. Refrigerator History and Business Guide for Entrepreneurs

a) Choose Your Market Segment

-

Value single-door: High-volume, budget-friendly models.

-

Premium inverter/smart: Efficient, quiet, and connected.

-

Commercial cold chain: Freezers, display fridges, walk-ins.

-

Eco-friendly niche: Low-GWP gases, recyclable materials, solar-ready systems.

b) What Customers Care About

-

Energy consumption per year (units) over wattage claims.

-

Temperature uniformity and fast cooling performance.

-

Noise levels, hinge quality, and door seals affect reviews.

c) Supply Chain and Certification

-

Key components: Compressor, condenser, evaporator, controller, insulation, doors, and lights.

-

Certifications: Energy Star or BEE star ratings, safety marks, and refrigerant labels.

-

After-sales edge: Quick gasket replacements and service availability.

d) Effective Marketing Ideas

-

Create a bill-savings calculator for real-world energy costs.

-

Show freshness comparison (e.g., leafy greens after 7 days).

-

Use exploded diagrams to explain airflow and insulation.

-

Offer long compressor warranties and doorstep repairs.

“Sell the savings and the silence — and back it with service.”

10. Refrigerator Buying Tips for Consumers

-

Family size: Capacity in liters matters more than door count.

-

Climate: Choose inverter or wide-voltage protection in unstable grids.

-

Food habits: Large freezer for meats; more fridge space for vegetables.

-

Space check: Measure width and door-open clearance before buying.

11. Quick Timeline Recap

-

Ancient to 1800s: Icehouses and clay pots

-

1834–35: Vapor-compression system (Perkins)

-

1851: Mechanical ice patent (Gorrie)

-

1876: Ammonia refrigeration (Linde)

-

1927: GE Monitor-Top home model

-

1987: Montreal Protocol phase-out

-

2000s–Today: Inverter tech and low-GWP refrigerants

Summary

The refrigerator’s journey from ice pits to smart appliances shows how science, sustainability, and business evolved together. Entrepreneurs can still innovate — from solar-powered coolers to climate-safe refrigerants — and shape the next era of global cooling.

For more on refrigeration technology history, visit ASHRAE’s Refrigeration Fundamentals or ScienceDirect’s guide on refrigeration systems.

You can also read our article on Top Global Refrigerator Brands 2025 or check our Made in India Refrigerator Brands.

One Response

It’s fascinating how refrigeration has shaped global trade and logistics, allowing perishable goods to be transported across the world. It’s hard to imagine modern commerce without it!