Non-Woven Bag Making Machine: What It Is, How to Get One, and Benefits

Introduction

With the ban on single-use plastic bags in many states across India, demand for eco-friendly alternatives like non-woven bags has skyrocketed. These bags are durable, reusable, recyclable, and affordable, making them a top choice for retail shops, supermarkets, and events.

For entrepreneurs, investing in a non-woven bag making machine is not just a business opportunity — it’s a step toward sustainability and profitability.

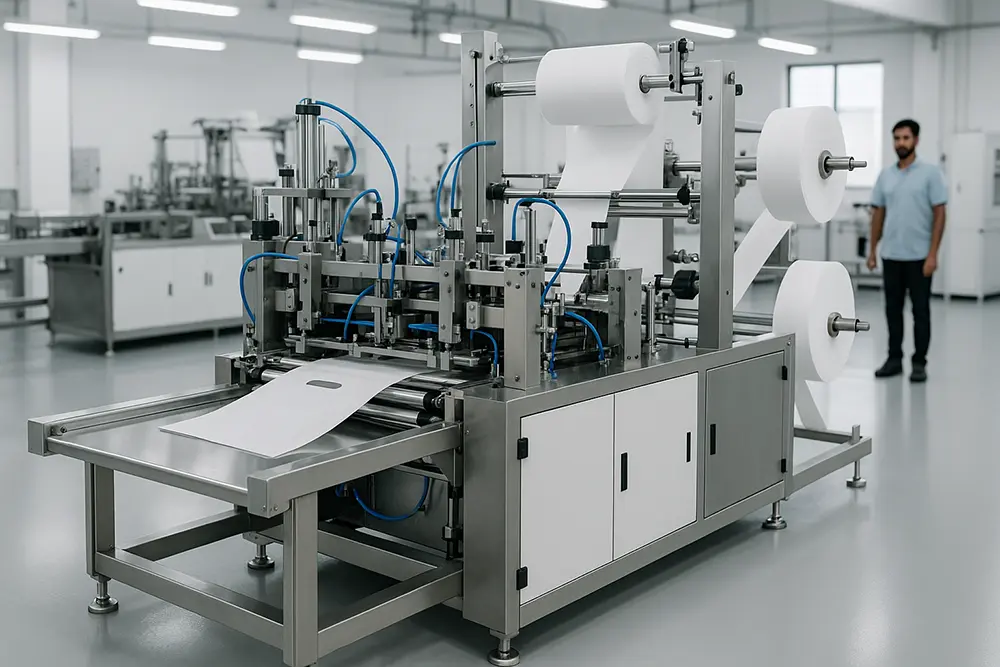

What Is a Non-Woven Bag Making Machine?

A non-woven bag making machine is a piece of industrial equipment that converts non-woven polypropylene fabric rolls into different types of carry bags through processes like:

-

Cutting (defining the bag size)

-

Sealing (ultrasonic/heat sealing edges)

-

Printing (optional branding, logo placement)

-

Folding and stitching (depending on design)

👉 Bags you can produce include:

-

Shopping bags

-

Box bags

-

D-cut and U-cut carry bags

-

W-handle bags

-

Gift and promotional bags

How to Get a Non-Woven Bag Making Machine in India

You can source machines through:

1. Indian Marketplaces

-

IndiaMART and TradeIndia list hundreds of suppliers.

-

Price range: ₹5 lakh – ₹15 lakh, depending on automation level.

2. Direct Manufacturers

-

States like Gujarat, Delhi, and Tamil Nadu have leading suppliers.

-

Benefit: Better service and spare part availability.

3. Chinese OEMs (Alibaba, Made-in-China)

-

Slightly cheaper, often imported models.

-

Downside: After-sales service and spares may be limited.

💡 Tip: For startups, begin with a semi-automatic machine and upgrade to fully automatic once volumes increase.

Benefits of a Non-Woven Bag Making Machine

✅ 1. High Demand & Profitability

Retailers, supermarkets, and FMCG brands are shifting to eco-friendly bags. Non-woven bags have strong repeat demand.

✅ 2. Government Support

Plastic bans + subsidies for eco-friendly businesses create an encouraging ecosystem.

✅ 3. Versatility

One machine can make different bag types with adjustable molds.

✅ 4. Eco-Friendly Impact

Non-woven bags are biodegradable and recyclable, helping you build a green brand image.

✅ 5. Fast Production

Modern automatic machines can produce 5,000–10,000 bags per day, depending on size and design.

✅ 6. Branding Opportunities

Logos, designs, and custom printing turn bags into mobile advertisements for clients.

Price & Investment Breakdown (2025)

| Machine Type | Price Range (Approx.) | Production Capacity | Best For |

|---|---|---|---|

| Semi-Automatic | ₹5 – ₹8 lakh | 2,000–4,000 bags/day | Small units |

| Fully Automatic | ₹9 – ₹15 lakh | 5,000–10,000 bags/day | Mid-size factories |

| High-Speed Advanced | ₹16 lakh+ | 12,000+ bags/day | Industrial setups |

Additional investment: Raw materials, printing setup, packaging, and labor.

5 Related Amazon Products for Packaging Entrepreneurs

1. Thermal Barcode Printer for Bag Labels

⭐ 4.6/5 | For branding and QR codes

🔗 View on Amazon

2. Heat Press Printing Machine

⭐ 4.5/5 | For logos on non-woven bags

🔗 View on Amazon

3. Eco-Friendly Non-Woven Fabric Roll (100m)

⭐ 4.6/5 | Raw material for bag making

🔗 View on Amazon

4. Industrial Sewing Machine (Heavy Duty)

⭐ 4.4/5 | For additional finishing needs

🔗 View on Amazon

5. Handheld Ultrasonic Sealer

⭐ 4.3/5 | For small repairs and prototypes

🔗 View on Amazon

Final Thoughts

A non-woven bag making machine is an excellent investment for anyone looking to start a low-risk, eco-friendly, and profitable business in 2025.

-

Start small with semi-automatic models

-

Scale up as demand grows

-

Focus on branding and packaging innovation to attract big clients

With strong government push and rising consumer awareness, the future of non-woven bag manufacturing in India looks brighter than ever.