History of Zipper Pouches for Food

From hand “zips” to stand-up, resealable packs

Quick idea in one line

A zipper pouch is just a flexible plastic bag + a reclosable zipper track—but it took a century of inventions (zipper → polyethylene film → press-to-close tracks → stand-up “Doypack”) to make today’s food pouches possible. Wikipedia+1

1) The building blocks before “pouches”

-

The zipper itself (metal): 1890s–1910s, Whitcomb Judson’s early “clasp locker” → Gideon Sundback’s modern interlocking-teeth zipper (patents 1913/1917). This made “zipping” a familiar action long before plastics. Wikipedia+2YKK Americas+2

-

Polyethylene film (PE): accidentally discovered at ICI in 1933; after WWII, LDPE film becomes cheap, sealable and food-contact friendly—perfect for bags. WIRED+1

Why this matters: You need a film you can heat-seal (PE) and a closure customers trust (zipper action). Join them → resealable food bags.

2) Plastic zipper → press-to-close “mini zips”

-

1951: Danish inventor Borge Madsen patents a plastic slide fastener (no metal teeth). It’s the ancestor of plastic bag zippers. interplas.com

-

1960–64: Flexigrip/Minigrip (Steven/Steve Ausnit) industrialize integral plastic zippers and license grocery-trade rights to Dow; this lets consumers buy resealable bags in supermarkets. interplas.com

-

1968: Ziploc (Dow) launches to U.S. consumers; later acquired by S. C. Johnson. Ribs, audible “clicks,” and colors follow in the 1980s–90s to signal a good seal. Wikipedia+1

Industrial side: Zip-Pak (ITW) and others supply press-to-close/slider zippers for packaging lines, not just retail box bags—so food brands can add zippers to their own pouches. zippak.com+1

3) The stand-up pouch enters (the “Doypack” moment)

-

1963: French engineer Louis Doyen (Thimonnier) invents the DOYPACK®—a heat-sealable stand-up pouch originally for juices/olives. The format (bottom gusset + laminated film) becomes a global staple. thimonnier.com+1

Game-changer: When you combine a Doypack (sits nicely on shelf) with a zipper (reclose after opening), you get today’s zipper stand-up pouch—ideal for snacks, dry fruits, pet food, coffee, grated cheese, etc.

4) What made zipper food pouches take off?

-

Materials: printable, strong film structures—PET/PE, PET/ALU/PE, OPP/CPP—with oxygen/moisture barriers (e.g., EVOH, foil) for aroma and shelf life. (Barrier choices vary by product.)

-

Convenience: open–pour–reclose beats tins and jars for many dry foods.

-

Machinery: horizontal/vertical FFS and premade-pouch lines started integrating zipper applicators at speed.

-

Retail display: stand-up, billboard-like front panel; works in boxes or peg holes.

-

Later upgrades: sliders, child-resistant zips, laser-score easy-open, degassing valves (coffee). (Suppliers include Zip-Pak and others.) zippak.com

5) Timeline you can drop into your blog

-

1913/1917: Sundback patents modern zipper. YKK Americas

-

1933: Polyethylene discovered at ICI; post-war LDPE film rises. WIRED

-

1951: Madsen files plastic slide-fastener patent. interplas.com

-

1964: Minigrip licenses grocery channel to Dow. interplas.com

-

1963: Doypack® stand-up pouch invented by Louis Doyen (Thimonnier). thimonnier.com

-

1968: Ziploc launches consumer resealable bags (Dow → later S. C. Johnson). Wikipedia

-

1980s–today: Industrial press-to-close/slider zips mainstream via suppliers like Zip-Pak; widespread on food pouches. zippak.com

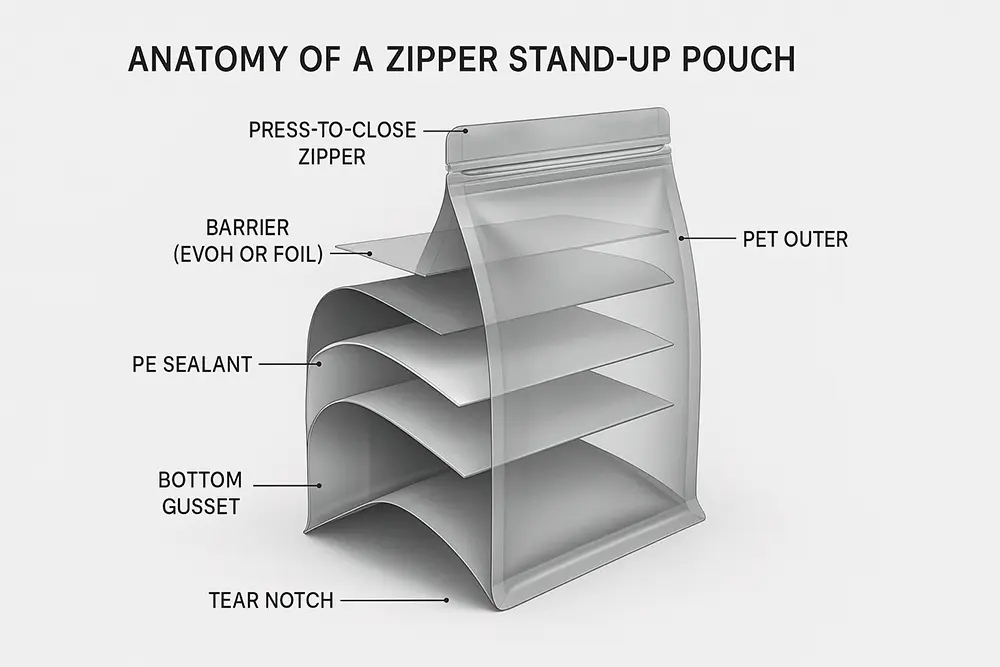

6) Anatomy of a zipper food pouch (simple)

-

Face/back webs: printable outer film(s) for looks + stiffness.

-

Barrier layer: keeps oxygen/moisture/odors out (EVOH/foil/met-PET depending on use).

-

Sealant layer: usually PE or CPP—melts and seals the pouch.

-

Bottom gusset: lets the pouch stand up.

-

Reclose system: press-to-close tracks or slider; placed above a tear-notch for tamper evidence.

7) Food safety & regulations (high level)

-

Films/inks/adhesives/closures must meet food-contact rules (region-specific).

-

Heat seals need strength + integrity; many brands perform drop and burst tests.

-

Coffee/spices often add valves or higher barriers to protect aroma and oils.

8) Sustainability: where zipper pouches are headed

-

Mono-material PE or PP pouches (zip + film in one polymer family) to improve store-drop-off or dedicated streams; R-600a not relevant here—focus is low-GWP inks/solvents, thinner gauges, and recyclable designs.

-

MDO-PE / BOPE structures target better clarity, stiffness, and recyclability.

-

Paper-based laminates with inner PE and reclosable strips for “paper touch” without losing sealability.

-

Refill pouches (detergents/foods) reduce rigid plastic per use.

(Exact recycling options depend on country programs and certification schemes.)

9) Choosing the right zipper pouch for your food (practical)

-

Dry snacks/cereals: PET/PE or OPP/CPP, standard press-to-close, 70–120 microns total, nitrogen flush optional.

-

Coffee: PET/ALU/PE (or high-barrier non-foil) + one-way valve + zipper; laser score for tidy tear.

-

Pet treats/spices: stronger lamination + aroma barrier; consider slider for frequent access.

-

Frozen: low-temp-tolerant sealant; anti-fog optional.

-

Baby/medical nutrition (dry): high QA on migration/odor, tamper-evident features, traceability.

10) Founders’ corner: costs, MOQ, and printing

-

MOQ: premade zipper pouches often 3k–10k per SKU (varies by vendor/country).

-

Printing: rotogravure for long runs; digital for fast, low-MOQ launches; matte/gloss, metallics, spot varnish.

-

Add-ons: euro-hole, clear window, pocket zipper, slider, rounded corners.

-

Unit economics: zipper adds cents per pack but lifts perceived value + repeat usage, often improving margin on premium SKUs.